Shaft line

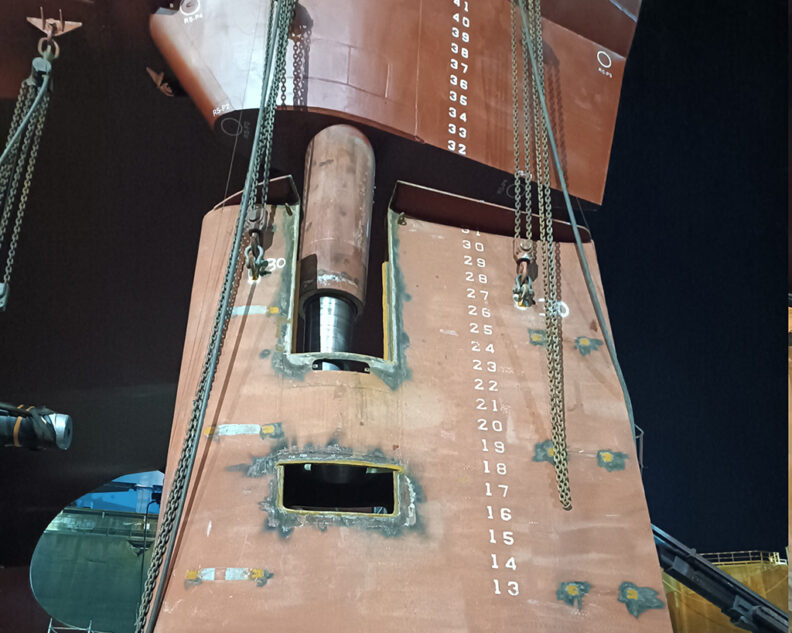

Disassembly of the main shaft line

Preparation and safety measures

- Securing and preparing the work area

Removal of propeller

- Draining lubricating oil from the stern tube

- Loosening and removing the propeller nut and securing key

- Using specialized lifting equipment to carefully detach the propeller from the shaft

Disconnection of shaft bearings and supports

- Removing stern tube seals

Extraction of the shaft

- Carefully withdrawing the shaft from the stern tube using controlled lifting techniques

- Supporting the shaft properly to avoid bending or structural damage

Disassembly of couplings and gearbox connection

- Unfastening coupling bolts connecting the shaft to the gearbox or engine

- Detaching any flexible or rigid couplings and inspecting for wear

Cleaning and Inspection

- Thoroughly cleaning all removed components, including the shaft, bearings and seals,

changing wore out parts including seals, bearings etc.

OD-Box overhaul

Preparation

- Shut valves, depressurize system

- Drain oil (if needed), ensure safety

Dismantling

- Disconnect and label oil lines

- Remove cover, filters, valves, sensors

Inspection

- Check valves, filters, seals, gaskets

- Look for corrosion, cracks, leaks

Cleaning & Repair

- Clean inside surfaces

- Replace worn parts, lubricate moving components

Reassembly

- Reinstall components with new gaskets/seals

- Reconnect oil lines

Testing

- Refill oil, open valves.

- Check pressure, flow, and for leaks

- Test sensors and valve operation

Final Checks

- Monitor system after startup

- Log work done and parts replaced